The proportion of elderly people in the population is rapidly growing worldwide. It is predicted that the numbers of patients suffering from falls due to aging and deterioration of bodily functions will increase in this super-aged world; at the forefront of this is Japanese society, which is graying at an unprecedented rate. In order to improve the quality of life (QOL) for these patients, devices for reconstructing bodily functions will become essential. Metals are candidates for materials of these devices used with the human body, in the form of implants, because of their strength, ductility and durability; actually, 80% of all implants today are made from metals. Our group focuses on the use of metallic biomaterials on the basis of physico-chemical approach.[1]

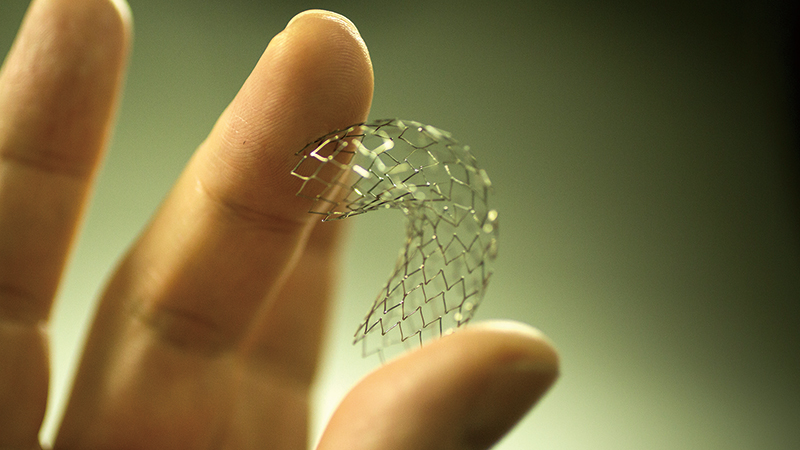

Fig.1 Vascular stent made of Cu-Cr alloy

We are working on the research to make stent* (Fig.1) more reliable and more durable by controlling microstructure of NiTi and Co-Cr alloys, mainly used as materials for self- as well as balloon-expandable stents, respectively. Both the fatigue strength of NiTi and the ductility of Co-Cr alloys have been improved through precipitation and phase-transformation control [2].

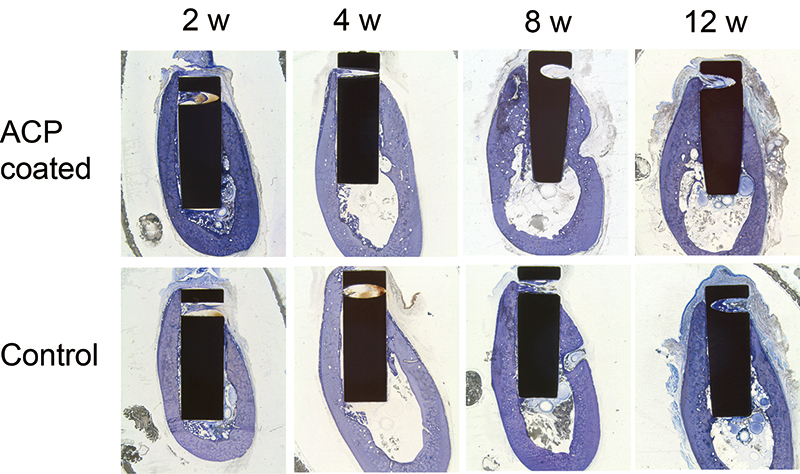

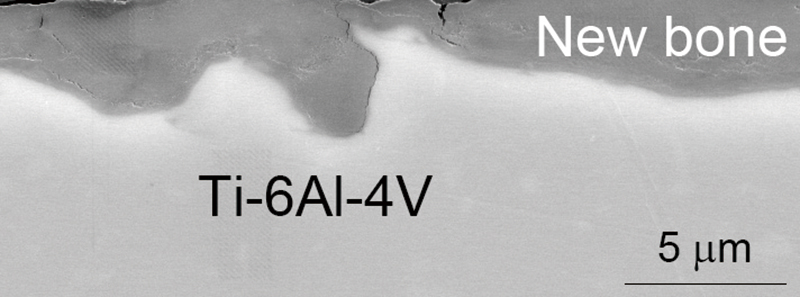

Fig.2 Interface between Ti implant and bone

Another study in our group is surface modification of metallic biomaterials, especially Ti and Ti alloys, giving these both the antibacterial activity and bone compatibility. It is well known that Ti possesses the unique property of osseointegration, which refers to direct connection from Ti to bone at the optical microscopic level. However, the fixation is influenced by the state of bones and interface. Therefore, surface modification is required for improving bone compatibility of Ti implants.For this reason, we prepared bioceramic coatings of bioresorbable ACP(amorphous calcium phosphate) (Figs.2 and 3) and photocatalytically-active TiO2 on Ti [3].

Fig.3 New bone formation on ACP-coated Ti

*A mesh tube medical device to spread the human body of the tubular part such as blood vessel from inside the lumen. The vascular stent market is more than ten billion US dollars and steadily increases year over year.

[1] T. Narushima: New generation metallic biomaterials, Metals for biomedical devices, Ed. M. Niinomi, Woodhead Publishing Limited, (2010), 355–378.

[2] Microstructure and mechanical properties of heat treated Co-20Cr-15W-10Ni alloy for biomedical application, K. Ueki, K. Ueda and T. Narushima Metall. Mater. Trans. A, 47 (2016) 2773–2782.

[3] T. Ueda, N. Kondo, S. Sado, O. Gokcekaya, K. Ueda, K. Ogasawara and T. Narushima: Ceramic coating of Ti and its alloys using dry processes for biomedical applications, Interface Oral Health Science 2016, Innovative Research on Biosis-Abiosis Intelligent Interface, Ed. K. Sasaki, O. Suzuki and N. Takahashi, Springer, (2017), 23–34